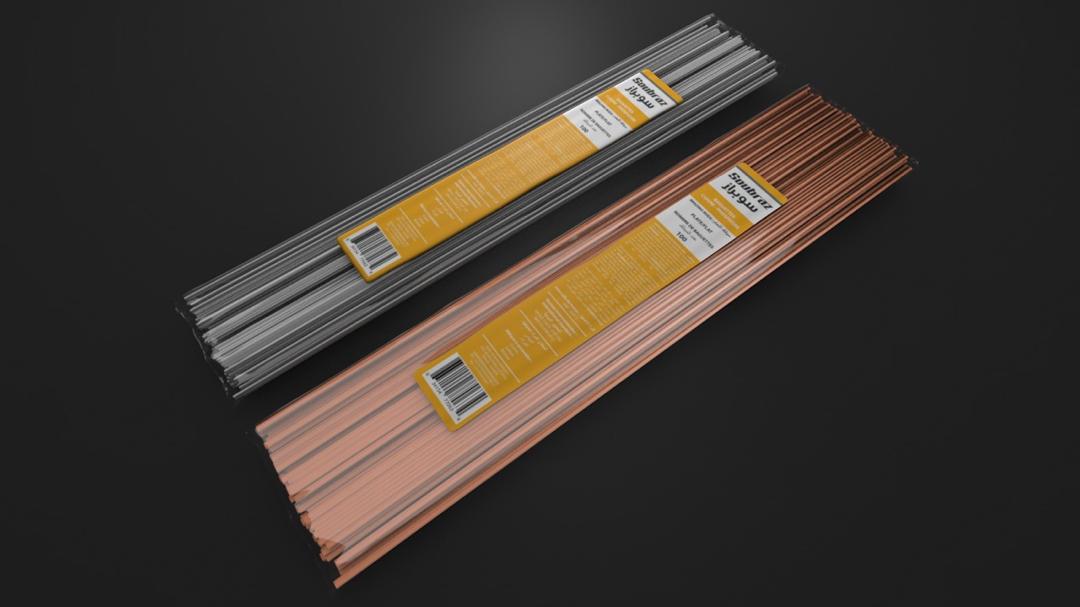

The SOUBRAZ range of soldering fluxes and flux removers is specially designed to optimize your brazing, soldering and activated soldering operations. Our formulations ensure perfect surface preparation, effective protection against oxidation, and optimum wettability to guarantee strong, clean and long-lasting solder joints.

Available in paste, liquid, gel or powder form, our fluxes cover all types of metal (copper, brass, steel, stainless steel, aluminum) and brazing processes (flame, induction, furnace, salt bath, etc.).

What is a flux or flux remover?

A flux (or stripper) is an active chemical substance applied to surfaces before or during brazing. It :

- Cleans metal oxides from surfaces.

- Protects against reoxidation during heating.

- Promotes filler metal spread and adhesion.

A good flux ensures a homogeneous metallurgical bond, without inclusions, porosity or harmful residues.

| Référence | Type | Base chimique | Plage de température | Métaux compatibles | Forme |

|---|---|---|---|---|---|

| FX-CuP | Flux pour brasure Cu-P | Borates & fluorures | 600–850 °C | Cuivre, laiton | Poudre ou pâte |

| FX-Ag | Flux brasure argent universel | Borax / Borique | 500–800 °C | Cu, laiton, acier | inox Pâte |

| FX-Sn | Flux brasure tendre | Résines activées | 180–300 °C | Cuivre, étain, laiton | Liquide ou gel |

| FX-Al | Flux spécial aluminium | Chlorures & fluoborates | 450–600 °C | Alliages Al, Zn | Poudre |

- Copper/phosphorus pipe brazing for air-conditioning and heating.

- Silver brazing fittings for gas installations, stainless steel parts or high stress.

- Soft soldering for electronics, plumbing or repairs.

- Preparation of parts for automated or controlled-atmosphere brazing.

- Excellent chemical activity at low temperatures.

- Good adhesion to vertical surfaces (paste/frost).

- Easy to clean up residues.

- Compatible with most common metals.

- Complies with industrial and REACH standards.

Available formats

- 125 ml / 250 ml / 500 ml bottles (liquid or gel).

- 100 g / 250 g / 500 g jars (paste).

- Sachets or buckets from 500 g to 5 kg (powder).

- Drums or cans for industrial use (to order).

Soubraz Quality Commitment

All our fluxes are :

- Formulated and laboratory-tested.

- Stable and consistent over time.

- Accompanied by complete technical data sheets and MSDSs.

- Adapted to the requirements of the HVAC, plumbing, energy, maintenance and electronics sectors.

Looking for a specific paint stripper?

Our technical office can help you :

Choose the right flux for your metal, temperature and process.

Create a customized flux for your production line.